Understanding aluminum casting and its applications across industries

Checking Out the Cutting-edge Procedures Behind Modern Light Weight Aluminum Factory Operations

Modern aluminum factory operations are going through significant change. Automation and AI are improving production methods, improving both efficiency and precision. The integration of 3D printing is improving mold production, while sustainability techniques are coming to be a lot more important. Each of these innovations plays an essential function in redefining the sector. Nonetheless, the ramifications of these changes expand beyond simple production effectiveness. What challenges and chances lie in advance for light weight aluminum foundries in this advancing landscape?

The Role of Automation in Aluminum Foundries

Moreover, automation adds to enhanced safety and security requirements within the foundry atmosphere. By transferring unsafe tasks to makers, human workers can concentrate on managerial duties and quality assurance, minimizing the threat of accidents. On top of that, data analytics stemmed from automated processes supply valuable insights into functional efficiency, leading to much better decision-making and continual renovation. As the demand for aluminum products grows, the adoption of automation innovations will likely broaden, better changing the landscape of light weight aluminum shop operations.

Improvements in Spreading Technologies

Current innovations in casting modern technologies are changing light weight aluminum shop procedures. Developments such as 3D printing assimilation, progressed alloy formulas, and automated procedure optimization are boosting efficiency and product quality. These growths are pivotal in meeting the developing demands of the market.

3D Printing Combination

Integrating 3D printing modern technology into aluminum foundry operations has reinvented standard casting methods, boosting both performance and precision. This innovative approach permits for the quick production of complex mold and mildews and cores, substantially lowering preparations and material waste. By utilizing additive production, foundries can produce intricate geometries that were formerly difficult or impossible to achieve with standard strategies. The adaptability of 3D printing additionally makes it possible for fast layout adjustments, fostering a more nimble manufacturing procedure. Additionally, this combination supports the usage of light-weight structures, which is increasingly vital in markets such as automotive and aerospace. As light weight aluminum factories continue to embrace 3D printing, they place themselves at the forefront of technical advancement, driving renovations in product high quality and functional abilities.

Advanced Alloy Formulations

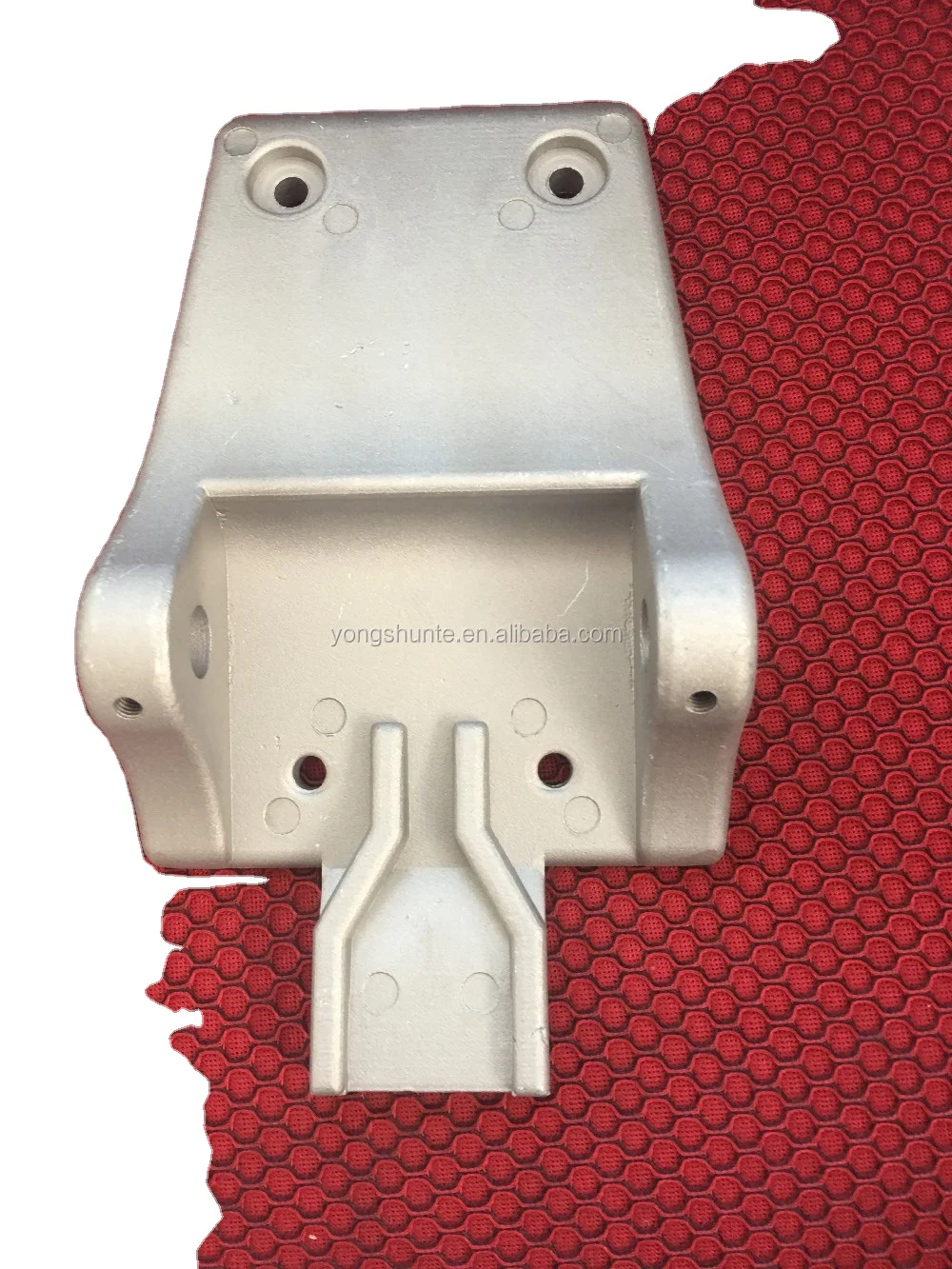

The advancement of advanced alloy solutions has greatly improved spreading modern technologies in aluminum shop operations. These formulas incorporate various aspects, such as magnesium, copper, and silicon, to boost mechanical residential or commercial properties and thermal resistance. By customizing the make-up of aluminum alloys, makers can accomplish certain efficiency attributes that fulfill the demands of varied applications, from vehicle parts to aerospace structures. The usage of advanced alloys likewise adds to decreased weight and boosted stamina, which are critical consider modern-day design. In addition, technologies in alloy advancement enable better fluidity during casting, resulting in improved surface coatings and lowered flaws. Overall, progressed alloy solutions stand for a substantial leap onward, placing aluminum foundries to fulfill the evolving requirements of different industries efficiently.

Automated Refine Optimization

Advancements in casting innovations have led the way for automatic process enhancement in aluminum foundry procedures. By integrating sophisticated software and real-time data analytics, shops can currently streamline manufacturing processes and improve quality control. Automated systems keep an eye on variables such as temperature, pressure, and air conditioning rates, enabling immediate changes that minimize defects and waste. Additionally, device discovering formulas assess historic efficiency data to forecast suitable settings, thus increasing performance and lowering cycle times. Robotics also play a significant function, taking care of repeated jobs that enhance safety and accuracy. Generally, these developments not only drive operational effectiveness yet also allow factories to meet the expanding need for high-quality light weight aluminum components in various sectors.

Smart Production and Sector 4.0 Assimilation

The integration of Smart Production and Sector 4.0 within aluminum factories is changing operational efficiency. By leveraging IoT modern technologies, automation, and robotics, shops can maximize production processes and decrease downtime. Additionally, data analytics offers important insights that improve decision-making and drive constant enhancement.

IoT in Factory Workflow

As makers significantly accept the Web of Points (IoT), factory operations are experiencing a transformative change in the direction of wise production and Sector 4.0 combination. Precision aluminum casting. IoT innovations allow real-time data collection and evaluation, improving decision-making processes and operational performance. Sensors and linked tools keep an eye on devices performance, material use, and ecological problems, enabling for aggressive maintenance and resource optimization. This connection cultivates a more agile production setting, where modifications can be made quickly in response to market needs. Additionally, IoT promotes improved traceability and quality assurance, as data from the whole production cycle can be conveniently accessed and evaluated. In general, the assimilation of IoT in factory operations substantially boosts efficiency and drives innovation in aluminum production procedures

Automation and Robotics Assimilation

Automation and robotics combination is revolutionizing aluminum foundry operations by boosting effectiveness and accuracy. This transformative method enhances processes such as molding, putting, and ending up, decreasing human mistake and increasing outcome uniformity. By using advanced robotic systems, factories can achieve higher production rates while preserving rigorous quality requirements. Automated systems likewise make it possible for real-time surveillance and flexible control, enabling swift changes to manufacturing specifications. In enhancement, the combination of robotics lessens labor prices and mitigates safety and security threats related to hands-on handling of molten steel. As shops welcome wise production principles integral in Market 4.0, the synergy between automation and robotics strengthens their competitive side, leading the way for sustainable growth and technology in the aluminum spreading market.

Data Analytics for Efficiency

Harnessing data analytics considerably improves efficiency within light weight aluminum factory procedures, lining up with wise manufacturing and Market 4.0 concepts. By leveraging real-time data collection and evaluation, factories can check manufacturing processes, forecast tools failings, and maximize resource allowance. This data-driven approach assists in insightful decision-making, allowing managers to enhance and determine traffic jams operations. Furthermore, predictive analytics equips shops to anticipate market demands, consequently decreasing waste and ensuring timely item shipment. Assimilation of information analytics with IoT gadgets boosts functional presence, cultivating a positive maintenance culture. Inevitably, carrying out these sophisticated analytical strategies not only improves productivity but likewise drives advancement, placing aluminum foundries to satisfy the progressing needs of the sector while preserving affordable edges in a rapidly altering landscape.

Lasting Practices in Aluminum Spreading

While the light weight aluminum casting market has actually typically dealt with environmental challenges, lots of factories are now embracing sustainable practices to alleviate their effect (Aluminum Casting Company). A substantial emphasis has been on recycling aluminum scrap, which not just lowers waste yet likewise saves energy contrasted to main Aluminum Foundry light weight aluminum manufacturing. Cutting-edge melting innovations, such as induction heating systems, improve energy efficiency and lower greenhouse gas discharges

Furthermore, shops are applying closed-loop water supply to lessen water usage and minimize thermal pollution. Using environment-friendly binders in mold-making processes is gaining grip, additional reducing damaging emissions.

Some centers are spending in renewable power resources to power procedures, straightening with international sustainability goals. By integrating these methods, the aluminum casting market is advancing towards an extra ecologically responsible future, showing that financial growth can exist together with environmental stewardship - Aluminum Foundry. These efforts show a dedication to sustainability and the importance of ecological accountability in production

Quality Assurance Innovations

As the aluminum casting market advances in the direction of sustainability, the relevance of quality assurance innovations becomes increasingly obvious. Modern aluminum factories are embracing innovative modern technologies to enhance their top quality guarantee procedures. Strategies such as real-time monitoring and data analytics permit makers to spot inconsistencies and defects early in the production cycle. Implementing computerized examination systems outfitted with device learning algorithms guarantees that items meet rigid quality requirements while reducing human error.

The assimilation of non-destructive testing techniques, such as ultrasonic and radiographic assessments, provides much deeper insights into the stability of castings without damaging the material. These advancements not just boost item reliability however additionally minimize waste, straightening with sustainability objectives. In enhancement, the adoption of standardized high quality frameworks assists streamline procedures throughout various shops, assuring uniformity in result. Jointly, these innovations are improving quality control, fostering a society of excellence within the aluminum spreading field.

Future Trends in Light Weight Aluminum Foundry Operations

What innovations lie ahead for aluminum foundry operations? The future of aluminum foundries is poised for change via improvements in automation, expert system, and sustainable techniques. The integration of robotics and automated systems is expected to boost performance and precision in the casting processes, decreasing human mistake and labor prices. Additionally, AI-driven analytics will certainly make it possible for real-time tracking and anticipating maintenance, maximizing operational performance and decreasing downtime.

Sustainability continues to be a prime focus, with shops significantly taking on environment-friendly practices, such as making use of recycled light weight aluminum and developing low-emission melting modern technologies. Innovations in 3D printing are also prepared for to change mold-making, permitting complicated geometries and reduced material waste. As the market welcomes digitalization, data-driven decision-making will end up being critical, enabling factories to react swiftly to market needs. Collectively, these patterns promise to redefine light weight aluminum shop operations, making them a lot more effective, lasting, and versatile to future challenges.

Frequently Asked Concerns

What Precaution Are Executed in Aluminum Shop Operations?

Aluminum foundry operations implement different precaution, including personal protective devices, air flow systems to handle fumes, regular safety training, emergency feedback strategies, and strict tracking of temperature level and devices to stop accidents and warranty worker safety.

Just How Do Foundries Take Care Of Workforce Training for New Technologies?

What Products Are Commonly Reused in Aluminum Foundries?

Light weight aluminum factories typically reuse scrap aluminum, consisting of post-consumer products like drink cans, automobile components, and building and construction materials. This recycling process decreases waste and preserves resources, adding to a much more lasting light weight aluminum production sector.

Just How Does Light Weight Aluminum Spreading Influence the Environment?

Aluminum casting impacts the atmosphere through energy-intensive processes, greenhouse gas discharges, and prospective regional contamination. Nevertheless, improvements in reusing and lasting techniques can reduce these effects, advertising a much more environment-friendly strategy to light weight aluminum production.

What Are the Normal Lead Times for Light Weight Aluminum Spreading Projects?

Normal preparation for light weight aluminum spreading tasks differ substantially, usually ranging from two to 6 weeks. Factors affecting these timelines include complexity, order dimension, and material accessibility, affecting overall manufacturing routines in factory operations.

Automation significantly plays a necessary duty in aluminum factories, enhancing efficiency and precision in the manufacturing procedure. Developments in casting technologies have led the means for automated process enhancement in light weight aluminum foundry operations. Utilizing data analytics considerably enhances efficiency within light weight aluminum shop procedures, straightening with wise production and Market 4.0 concepts. A considerable focus has actually been on recycling light weight aluminum scrap, which not only minimizes waste yet likewise saves power compared to key aluminum manufacturing. Aluminum shops generally reuse scrap light weight aluminum, consisting of post-consumer products like drink cans, vehicle components, and building materials.